FENGYU Premium Rack End Manufacturer Delivering Precision for Global Automotive Aftermarket

Traditionally, ice storage is thought to only balance grid loads by shifting energy use from peak to off-peak hours. However, H.Stars’ innovative ice storage all-in-one unit breaks this stereotype, offering more versatile and cost-effective advantages.

This all-in-one ice storage unit serves a wide range of applications. In industrial refrigeration processes, it precisely controls water temperatures, ensuring stable operation in temperature-sensitive production stages—boosting product quality and efficiency. For air conditioning systems, its value shines: by making ice during off-peak (lower-cost) night hours and releasing cold energy during peak daytime, it not only cuts operating costs but also enhances AC performance, delivering a more comfortable and stable indoor environment. Additionally, the unit reduces required installed capacity, eliminating the need for businesses to invest heavily in large-scale refrigeration equipment and slashing initial construction costs.

Economically, the all-in-one unit’s advantages stand out. While peak shaving reduces electricity bills, its integrated design combines multiple functions, shrinking footprint and lowering installation, commissioning, and long-term maintenance costs. Previously, achieving these functions might have required multiple separate devices—costly to purchase, with complex coordination and management between them. Now, one all-in-one ice storage unit handles it all.

H.Stars’ ice storage all-in-one chiller, with its multi-purpose technology, offers a new refrigeration solution for industrial and commercial sectors. It redefines ice storage beyond a single function, maximizing economic benefits through integration. Whether for energy-conscious enterprises or spaces demanding high AC comfort, this unit is a valuable choice, leading the refrigeration industry toward greater efficiency and affordability.

When it comes to medium-sized excavators, two of the most popular models are the Caterpillar CAT 320D and the Komatsu PC200-8. Both machines are trusted worldwide for earthmoving, roadwork, and construction projects. But how do they compare, and which one is the better choice for your business? Let’s break it down.

CAT 320D is powered by a Cat C6.4 ACERT engine, delivering around 138 kW (185 hp). It offers strong digging force and smooth hydraulic control, making it highly efficient for heavy-duty work.

Komatsu PC200-8 comes with a Komatsu SAA6D107E-1 engine, producing about 110 kW (148 hp). While slightly lower in horsepower, it is known for reliability and fuel efficiency.

Verdict: CAT 320D provides more horsepower and stronger digging force, ideal for demanding operations. Komatsu 200-8 offers a balance of performance and efficiency, making it suitable for general construction work.

CAT 320D focuses on productivity, sometimes at the expense of higher fuel consumption. However, its advanced hydraulics help optimize energy use.

Komatsu PC200-8 features Komatsu’s fuel-saving technology, making it one of the more economical excavators in its class.

Verdict: If fuel cost is a major concern, Komatsu PC200-8 has the edge.

CAT 320D is well-regarded for operator comfort, with spacious cabins, ergonomic controls, and reduced vibration. Advanced monitoring systems improve machine management.

Komatsu PC200-8 also offers a comfortable cab with low noise levels and easy-to-use controls. It includes Komtrax, Komatsu’s GPS-based tracking system, for real-time monitoring.

Verdict: Both offer modern operator-friendly features, but Komatsu’s Komtrax system provides added fleet management benefits.

CAT 320D is famous for durability and long service intervals. Caterpillar’s global support network makes parts and service widely available.

Komatsu PC200-8 is also highly reliable, with strong undercarriage and robust hydraulics. Komatsu’s support is solid, but parts availability can vary depending on the region.

Verdict: Both machines are durable, but CAT’s global parts support gives it a slight advantage.

CAT 320D holds higher resale value in most markets due to strong demand and brand reputation.

Komatsu PC200-8 also retains good value but generally slightly lower than CAT.

Choose CAT 320D if you need maximum digging power, global support, and higher resale value. It’s ideal for heavy-duty contractors who prioritize productivity.

Choose Komatsu PC200-8 if you want fuel efficiency, lower operating costs, and reliable performance for medium workloads. It’s a great option for contractors looking to reduce expenses while maintaining solid performance.

Both excavators are excellent choices in the 20-ton class, and the best decision depends on your project requirements, budget, and long-term fleet strategy.

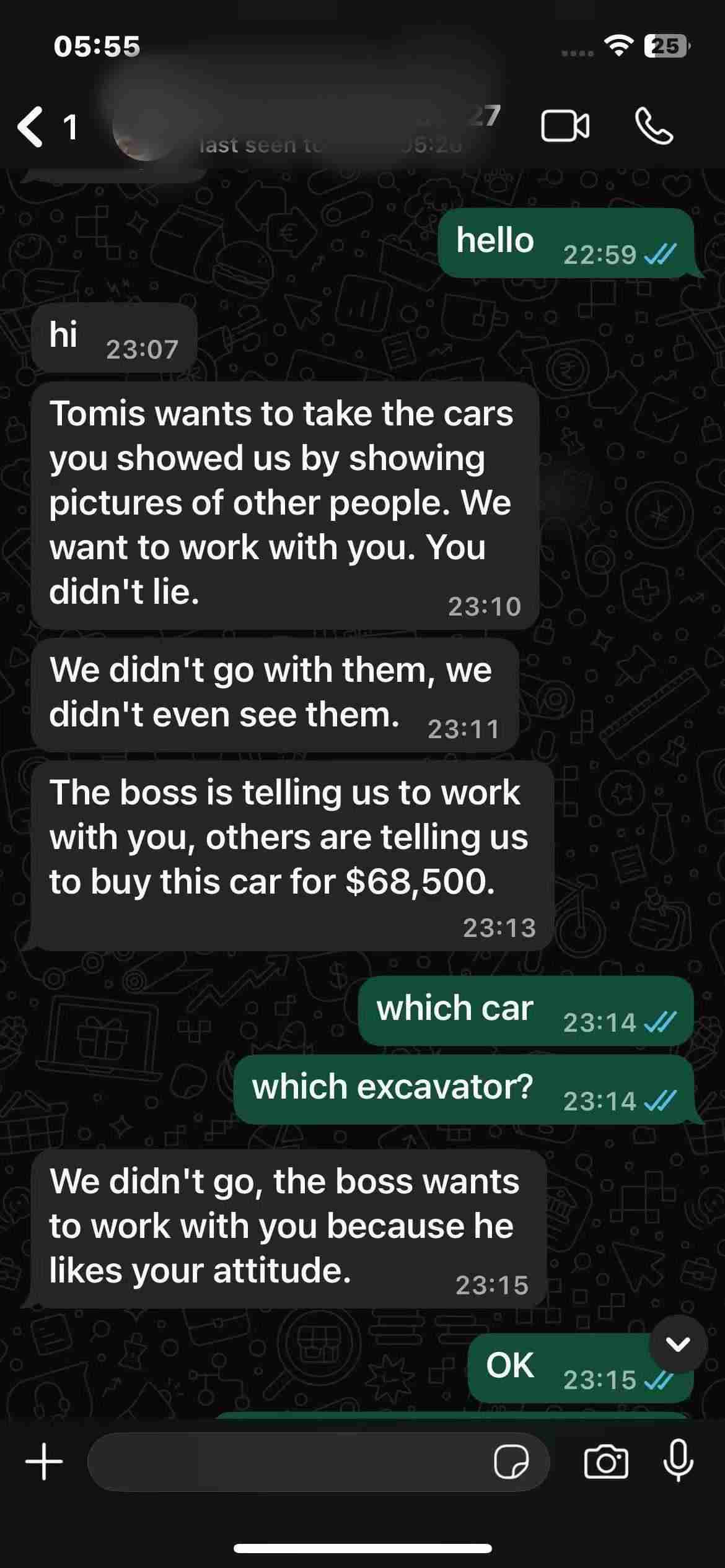

We recently received a heartfelt review from afar. Though we are separated by great distance, it does not hinder our sincere mutual well-wishes!

Firstly, its advanced hydraulic control system performs excellently, operating more smoothly and with greater precision than any comparable model we have tested. Even under complex working conditions, the equipment maintains stable efficiency, providing strong support for the smooth progress of our projects.

Secondly, the humanized cab design is truly commendable. The equipped air conditioning system offers operators a comfortable working environment in high-temperature conditions, which is crucial for our prolonged outdoor operations during the summer. The excellent working environment not only enhances productivity but also reflects your company's human-centric care for operators.

Our management ultimately decided to purchase your equipment in bulk precisely because they valued your company's professional and pragmatic work attitude as well as your commitment ,This batch of equipment will be used for our upcoming major infrastructure projects. We are confident that with its exceptional reliability, outstanding efficiency, and advanced features, it will become the backbone of our project construction.

We look forward to establishing a long-term strategic partnership with your company, working together to contribute to the thriving construction industry here. We also wish your company continued growth and success, and we anticipate achieving even greater accomplishments in our future cooperation!

When buying a used excavator, one of the most important factors to inspect is the engine condition. The engine is the heart of any excavator, and a poor-quality engine can lead to costly repairs, downtime, and low efficiency on site. Whether you are purchasing for a project in Africa, Asia, or the Middle East, knowing how to assess the excavator’s engine will help you make the right decision.

In this blog, we will guide you through the key steps to evaluate if an excavator engine is in good working order before buying.

A healthy engine should start smoothly without excessive cranking. Warning signs include:

Hard starting, especially in warm weather.

Excessive smoke at start-up.

Unusual knocking or rattling sounds.

Tip: Always request a cold start test. This shows how the excavator performs when the engine has been sitting idle for hours.

Exhaust smoke can reveal much about the condition of the engine:

Blue smoke → burning oil (possible worn piston rings or valve seals).

Black smoke → incomplete fuel combustion (possible injector or turbo issues).

White smoke → coolant leakage or head gasket problem.

Healthy engines should produce little to no smoke after warming up.

Engines in good condition should run smoothly. Be cautious of:

Knocking sounds → may indicate worn bearings or piston issues.

Tapping sounds → possible valve or injector problems.

Grinding noises → potential timing gear or accessory failure.

Check the engine oil color – dark black oil may indicate overdue service, while milky oil could mean coolant leakage.

Inspect hydraulic oil – low or dirty fluid can affect both the engine and overall excavator performance.

Regular maintenance history is a good sign of a well-kept machine.

Excavator engines are built for long life, but:

Over 10,000 hours may require major inspection.

Compare machine condition with hour meter reading – if it looks heavily worn but shows low hours, it may be tampered.

Ask the seller to operate the excavator under real working conditions:

Digging or lifting heavy loads.

Swinging the boom while tracking.

The engine should maintain steady power without stalling or producing excessive smoke.

A reliable service history is the best proof of maintenance.

Also, confirm the engine model – brands like Cummins, Isuzu, Mitsubishi, and Hyundai engines are known for durability and easy parts availability in African markets.

Inspecting an excavator engine is essential before purchase. By checking start-up performance, exhaust smoke, unusual noises, oil condition, operating power, and service history, you can avoid costly mistakes and ensure you are buying a reliable excavator for your construction project.

For buyers in Africa and worldwide, investing in the right machine with a strong engine means higher productivity and lower maintenance costs.

When a modern excavator effortlessly scoops 5 tons of earth, its steel arm channels not just raw power—but a million generations of human ingenuity in our ancient struggle with the land. Join us as we unveil the legendary ancestors that reshaped our planet's contours!

Chapter 1: Genesis – Muscles and Levers (4000 BC – 1700 AD)

1.1 The Original "Excavators" – Human Hands

Primitive Era: Clam shells as shovels, animal bones as picks

Egyptian Marvel: 100,000 workers hand-dug the Pyramids of Giza (moving 2.5-ton stones = 1.5 hours of work for a modern 20-ton excavator)

1.2 Dawn of Leverage Civilization

Warring States Period : Earliest mechanical digging apparatus

Archimedes' famous boast: Warship-moving experiments demonstrating lever principles

Chapter 2: Steam Age – Iron Behemoths in Smoke (1780-1912)

2.1 Game-Changing Milestone

1829 Patent: William Otis' steam-powered rail-mounted excavator

Efficiency Revolution: Daily output = 200 laborers (still required 6 operators)

2.2 Transcontinental Engineering Saga

Panama Canal Project (1881):

Note: 30,000 workers died from yellow fever – underscoring machinery's humanitarian value

Chapter 3: Internal Combustion Revolution – Awakening of Petroleum Bloodline (1914-1945)

3.1 War-Driven Evolution

WWI trench-digging demands → Birth of track-mounted gasoline excavators

Key breakthrough: Hydraulic pilot controls replace mechanical linkages (reducing operating force by 90%)

3.2 Explosion of Iron Species

Model Milestone Modern Descendant

1923 Bucyrus First 360° rotating excavator Caterpillar slewing base

1935 Lorain Hydraulic backhoe patent Komatsu PC backhoe design

Chapter 4: Hydraulic Era – Micron-Level Precision (1948-Present)

4.1 French Genius

1948 Poclain invents fully hydraulic excavator

300% increase in power transmission efficiency

Enabled compound movements (modern machines control 7 cylinders simultaneously)

4.2 The Renaissance Philosophy of Used Machinery

At Lianyan Machinery's Refurbishment Center, we rebirth legends:

1950s-era steel arms: Laser-calibrated to 0.05mm valve spool precision

1978 Caterpillar's first hydraulic unit: 40% fuel reduction via electronic upgrades

When planning a construction project, one of the biggest investments is equipment. Excavators are essential machines for digging, lifting, and earthmoving tasks. However, purchasing a brand-new machine can put a heavy strain on your budget. This is why many contractors and businesses choose to buy a used excavator for sale, as it offers both affordability and reliability.

Buying a used construction excavator is far more affordable than purchasing new. Instead of spending a large sum upfront, you can acquire a reliable second-hand excavator at a fraction of the cost. This means you can use your budget more wisely—whether that’s buying additional equipment, hiring more workers, or expanding your operations.

A second-hand excavator pays for itself much faster than a new one. Since your initial cost is lower, your projects start generating profits quickly. This is especially beneficial for small to mid-sized contractors who want to grow without heavy debt.

High-quality used excavators are built to last and can perform almost as efficiently as new machines. Many suppliers provide detailed inspection reports, maintenance records, and even limited warranties. When buying from a trusted seller, you can be confident that your excavator is reliable and ready to work.

The used excavator market offers a broad range of models and sizes, allowing you to find the right machine for your project needs. Unlike new equipment that may require long waiting times, used machinery is often ready for immediate delivery, saving valuable time on urgent projects.

Just like cars, new heavy machinery loses value quickly in the first few years. By choosing a used excavator, you avoid the steepest depreciation curve. This also means that if you decide to sell or upgrade in the future, your machine will retain more resale value.

Buying a used construction machine helps reduce environmental impact. Instead of manufacturing a brand-new excavator, reusing and extending the life of existing equipment conserves resources and reduces waste. This makes it not only a cost-effective choice but also a responsible one.

When buying a used excavator for sale, always inspect the machine’s engine, hydraulic system, undercarriage, and overall wear. Request a complete maintenance history and ensure there are no leaks, cracks, or unusual noises. A reliable supplier should provide a pre-shipment inspection report.

To guarantee quality, buy from reputable used excavator suppliers who offer warranties or after-sales service. Check working hours, ask for inspection videos, and confirm the machine has been regularly serviced. A well-maintained used construction excavator can work as efficiently as a new one.

Always use secure and traceable payment methods such as bank transfer (T/T), letter of credit (L/C), or escrow. Avoid cash payments for large amounts. Ensure the sales contract clearly states the warranty terms, delivery timeline, and after-sales support to protect your investment.

Yes—provided you work with an experienced exporter. Trusted suppliers usually have certifications, verified business licenses, and customer reviews. They also conduct two pre-shipment inspections and offer payment protection options to ensure transaction safety.

Compare machine prices, hours worked, and overall condition. Sometimes a slightly newer affordable used excavator with lower working hours offers better long-term value. Balancing cost and quality ensures you make the smartest purchase.

Purchasing a used excavator for sale is not just a way to save money—it’s a strategic business move. From lower costs and faster ROI to proven performance and environmental benefits, a used machine can deliver everything you need for your projects.

By paying attention to quality checks and secure payment methods, you protect your investment and ensure long-term success. With the right supplier, buying a second-hand excavator becomes a safe, reliable, and profitable choice for contractors and construction companies worldwide.

When a 20-ton steel arm effortlessly hoists a loaded pickup truck, it's not just mechanical power at work—but a symphony of hydraulic alchemy. Today we reveal how refurbished excavators maintain their earthmoving might!

1. Source of Power: Pascal's Law in Industrial Revolution

"Give me a fulcrum, and I shall move the world" — Archimedes' wisdom finds new expression in hydraulics:

Force = Oil Pressure × Piston Area

2. Guardians of Refurbished Power

Time wears steel, but scientific restoration resurrects strength

At our Hefei Refurbishment Center, we subjected a 2008 Komatsu PC200-8 to extreme testing:

3. The Art of Strength: Where Power Meets PrecisionThink excavators only deliver brute force? Witness their "mechanical ballet":

Surgical Precision

Cracking eggshells with a breaker hammer (yolk intact)

Achieving millimeter control via proportional solenoid valves

Intelligent Power

Pressure sensors preventing overloads in real-time

Cushioning technology eliminating impact shocks

4. Buyer's Strength Diagnostic Guide

Three field tests to verify performance:

Lift Endurance Test

Raise rated load to maximum height → Lock controls

Pass standard: <3° arm drop in 10 minutes (measured with inclinometer)

Compound Motion Challenge

Simultaneously operate boom/stick/swing (trace ∞-shaped path)

Monitor movement fluidity → Listen for pump abnormalities

"We restore not just machines, but earthmoving strength you can entrust your projects to."

In August, China is swept by sweltering heatwaves and blazing sunshine. During this intensely hot season, we welcomed a group of guests from afar—a delegation of clients from Uzbekistan. With a clear purpose for their visit, they arrived at the construction machinery base to personally test the Hyundai 210WVS wheel excavator and evaluate its performance and reliability on site.

A Warm Encounter: A Journey of Cooperation Across the Silk Road

As a key node in the "Belt and Road" initiative, Uzbekistan has seen growing infrastructure development needs in recent years, driving a strong demand for high-performance construction machinery. At the machinery base, the clients were warmly received.

On-Site Testing: A Display of Performance Under High Temperatures

The test was arranged at a dedicated proving ground, where the temperature reached 38°C, mimicking typical summer conditions in Uzbekistan. In such a demanding environment, the Hyundai 210WVS wheel excavator faced its "ultimate test."

Once the equipment started, it smoothly performed a series of challenging operations.

Precise digging demonstrated its excellent hydraulic control system.

Flexible rotation and movement highlighted the advantages of its wheeled chassis.

Efficient loading operations showcased its powerful performance.

Particularly impressive was the equipment’s cooling system, which performed excellently under sustained high temperatures. The engine’s water temperature remained within the normal range, demonstrating outstanding environmental adaptability.

Client Feedback: Recognition and Expectations

The on-site test provided the clients with a more intuitive understanding of the Hyundai 210WVS wheel excavator. They expressed, "This visit to China has been highly rewarding. We not only witnessed the outstanding performance of Hyundai’s equipment but also experienced your company’s professionalism and sincerity. The 210WVS fully meets the needs of our infrastructure projects."

Preliminary discussions were held regarding future cooperation, with the clients expressing their intention to proceed with bulk purchases and hoping to establish a long-term partnership.

Conclusion: Quality Wins Trust, Cooperation Creates the Future

Amid the scorching summer heat, the Hyundai 210WVS wheel excavator spoke with its capabilities and won recognition through its quality. This test not only highlighted the technical advantages of Hyundai’s construction machinery but also built a bridge for cooperation between Chinese and international enterprises. Moving forward, Hyundai will continue to prioritize innovation and customer focus, offering more high-performance and reliable construction machinery products to contribute to global infrastructure development.

When contractors are looking for a reliable and cost-effective excavator, the Hyundai 220LC-9S often becomes their first choice. This model is well recognized for its stable performance, easy maintenance, and excellent value for money, making it popular in Africa, Asia, and the Middle East.

Here are the main reasons why customers continue to choose the Hyundai 220LC-9S:

1. Stable and Reliable Performance

The Hyundai 220LC-9S is built to handle demanding work environments such as earthmoving, road building, and mining projects. Its powerful Cummins/Hyundai engine provides consistent digging force, strong lifting capacity, and reliable fuel efficiency. Contractors appreciate its ability to perform steadily even under tough soil and rock conditions.

2. Easy Access to Spare Parts

Another key advantage of the Hyundai 220LC-9S is the availability of spare parts. Compared with other brands, Hyundai has a well-established parts supply network. This makes it easy for customers in Africa and beyond** to find replacement parts quickly, reducing downtime and ensuring continuous project progress.

3. Comfortable and User-Friendly Cabin

Operator comfort is essential for productivity. The Hyundai 220LC-9S features a spacious cabin with ergonomic controls, adjustable seating, and advanced monitoring systems. These features reduce fatigue and increase efficiency, especially for operators working long shifts.

4. Excellent Value for Money

The Hyundai 220LC-9S delivers the perfect balance of affordable purchase cost, low maintenance expenses, and strong resale value. This makes it an ideal investment for contractors looking to expand their fleet with a reliable and durable excavator.

Conclusion: A Smart Choice for African Projects

The Hyundai 220LC-9S excavator is trusted by contractors worldwide for its reliability, spare parts availability, operator comfort, and overall value. For companies aiming to succeed in African infrastructure and construction projects, it remains one of the best investment choices.

Looking for a Hyundai 220LC-9S excavator?

We supply high-quality used Hyundai excavators and other construction machinery, shipped directly to Africa and global markets.

Contact us today to get the best price on a Hyundai 220LC-9S and expand your fleet with confidence!