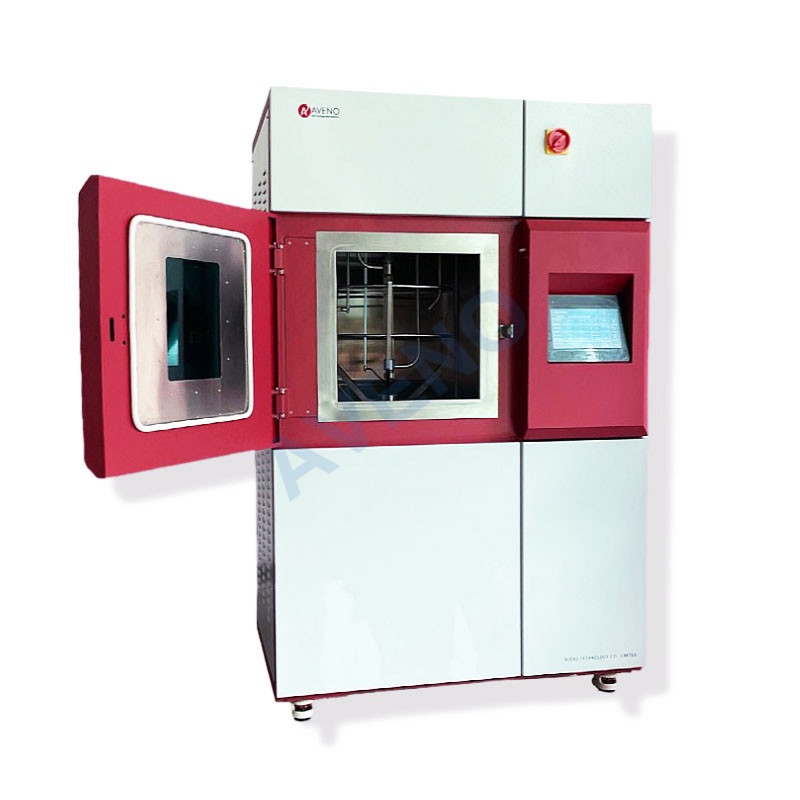

In the fields of research and testing of new energy devices such as lithium-ion batteries and supercapacitors, a reliable and precisely structured battery case is of vital importance. The 304ss Meshed Coin Cell Cases CR20XX series, with its outstanding material properties, unique grid design and wide adaptability, has become the preferred solution for research institutions and enterprise laboratories.

304 Stainless Steel: Dual Guarantee of Performance and Stability

304ss (304 stainless steel) serves as the core material for the shell of the CR20XX series grid coin cell, forming the foundation for achieving excellent performance. This stainless steel contains 18% chromium and 8% nickel, belonging to the austenitic stainless steel family, and possesses three core advantages: corrosion resistance, mechanical stability, and chemical inertness.

In the battery testing environment, the electrolyte often has strong corrosiveness. Ordinary metal materials are prone to oxidation or dissolution, leading to battery shell leakage, short circuit, and even failure of the experiment. 304 stainless steel forms a dense oxide film through chromium elements, effectively resisting the erosion of electrolyte. Even when in contact with common electrolyte components such as carbonates and lithium hexafluorophosphate for a long time, it can still maintain structural integrity. At the same time, its tensile strength reaches 520 MPa, and the yield strength is approximately 205 MPa. During assembly, it is less likely to deform under the pressure of bolt tightening, ensuring the sealing performance of the battery shell.

More importantly, the chemical inertness of 304 stainless steel can prevent secondary reactions with electrode materials. During the migration of lithium ions, the shell will not release impurity ions that interfere with the battery's charging and discharging cycles, ensuring the accuracy of experimental data. This characteristic makes it particularly outstanding in scenarios requiring long-term cycle testing, providing researchers with a stable experimental benchmark.

Grid Structure: Innovative Design for Optimizing Mass Transfer and Heat Dissipation

The "Meshed" design of the CR20XX series is a key feature that distinguishes it from traditional coin cell casings and is the core competitiveness that sets it apart in high-performance testing. The grid structure is typically located at the bottom or sides of the casing and is formed by precisely laser-cutting uniform micron-sized holes, which not only maintain structural strength but also achieve three major functional breakthroughs.

Firstly, the efficiency of electrolyte infiltration is improved. The grid holes provide a rapid flow channel for the electrolyte, allowing the electrode materials to be fully infiltrated after assembly within a short period of time, reducing the testing waiting time caused by the slow diffusion of electrolyte in traditional sealed casings, especially suitable for research scenarios requiring frequent experiments. Secondly, the grid structure enhances the heat dissipation capacity of the battery casing. During high-rate charge and discharge tests, a large amount of heat is generated inside the battery, and the grid design increases the contact area with the external environment, accelerating heat dissipation and avoiding the impact on battery performance or potential safety hazards due to excessively high temperatures.

In addition, the grid structure provides the possibility for in-situ characterization experiments. In some research scenarios, real-time monitoring of electrode material changes is required through methods such as X-ray diffraction and Raman spectroscopy. The grid holes can serve as a signal transmission window, enabling in-situ analysis without damaging the battery structure, providing convenience for material mechanism research.

CR20XX Series: A Model Matrix Tailored to Diverse Testing Requirements

The CR20 series is not a single model product but encompasses multiple sub-specifications to accommodate different electrode sizes and testing needs. The most common models include CR2016, CR2025, and CR2032. The suffixes after the numbers represent the diameter and thickness of the battery case (in mm), for example, CR2032 indicates a diameter of 20mm and a thickness of 3.2mm. This standardized size design is consistent with commercial button batteries, facilitating researchers to directly adopt the mature electrode preparation process.

There are differences in the structural details of the grid coin cell cases of different models. The CR2016 is thinner and is suitable for low-material-usage micro testing, reducing experimental costs; the CR2032 is thicker and has ample internal space, suitable for mounting thicker electrode sheets or composite structure devices, such as solid-state electrolyte batteries for testing. Additionally, some manufacturers also offer enhanced models with pressure relief valves. When the internal pressure of the battery rises abnormally, the pressure relief valve will automatically open to release the pressure, further enhancing the experimental safety.

It is worth noting that the grid cases of the same series maintain uniform compatibility in accessories. Whether it is CR2016 or CR2032, the accompanying gaskets, spring clips, sealing rings, etc. are interchangeable, reducing the complexity of laboratory material management. At the same time, the hole diameters and distribution densities of the grid structure are optimized according to the model to ensure consistent mass transfer and heat dissipation performance of different size cases, providing reliable condition control for comparative experiments.

Application scenarios: Full coverage from basic research to industrial testing

The application scenarios of the 304ss Meshed Coin Cell Cases CR20XX series have extended from university laboratories to the R&D centers of new energy enterprises, serving as an important bridge connecting basic research and industrial application. During the material research stage, researchers utilize its high sealing and chemical stability to test the electrochemical properties of new cathode materials (such as ternary materials, lithium iron phosphate) and anode materials (such as silicon-based anode, hard carbon). Through the efficient mass transfer characteristics of the grid structure, they can quickly obtain key data such as charge-discharge curves and cycle life.

In the optimization of the electrolyte system, this series also performs well. Whether it is liquid electrolyte, gel electrolyte or solid electrolyte, the grid shell can adapt to its testing needs: for liquid systems, the grid accelerates the infiltration of the electrolyte; for solid systems, its rigid structure can provide stable interface pressure, promoting ion conduction. In the research of solid-state batteries, the CR2032 model is often used to simulate the laminated structure of actual devices and evaluate the interface compatibility between the electrolyte and the electrode.

The quality inspection process in the industrial sector also cannot do without this series of products. Battery manufacturers use the CR20XX series grid shells to conduct random inspections of raw materials, quickly determining key indicators such as the uniformity of electrode paste coating and the thermal stability of the separator. The test results have a good correlation with the performance of mass-produced batteries, providing strong support for quality control on the production line. In addition, in battery recycling research, the grid shell facilitates disassembly and material recovery, reducing the cost of handling experimental waste.

The 304ss Meshed Coin Cell Cases CR20XX series, with its outstanding performance of 304 stainless steel, innovative grid structure design and a wide range of model options, provides a reliable carrier for the research and testing of new energy devices. Its advantages in corrosion resistance, mass transfer efficiency, and heat dissipation performance make it a key tool for connecting basic research and industrial applications. With the rapid development of new energy technology, this series will continue to be upgraded and improved, contributing more to the research and development of high energy density and high safety batteries. For researchers, a deep understanding of its performance characteristics and a reasonable selection of models will effectively enhance experimental efficiency and data reliability, and accelerate the industrialization process of new materials and new devices.