What does a rotary rack oven do?

A rotary rack oven is a type of commercial baking oven designed for high-volume baking operations. It is characterized by its rotating rack system, which ensures even baking by rotating trays of products inside the oven. This type of oven is commonly used in bakeries and pastry shops for baking bread, cakes, cookies, and other baked goods.

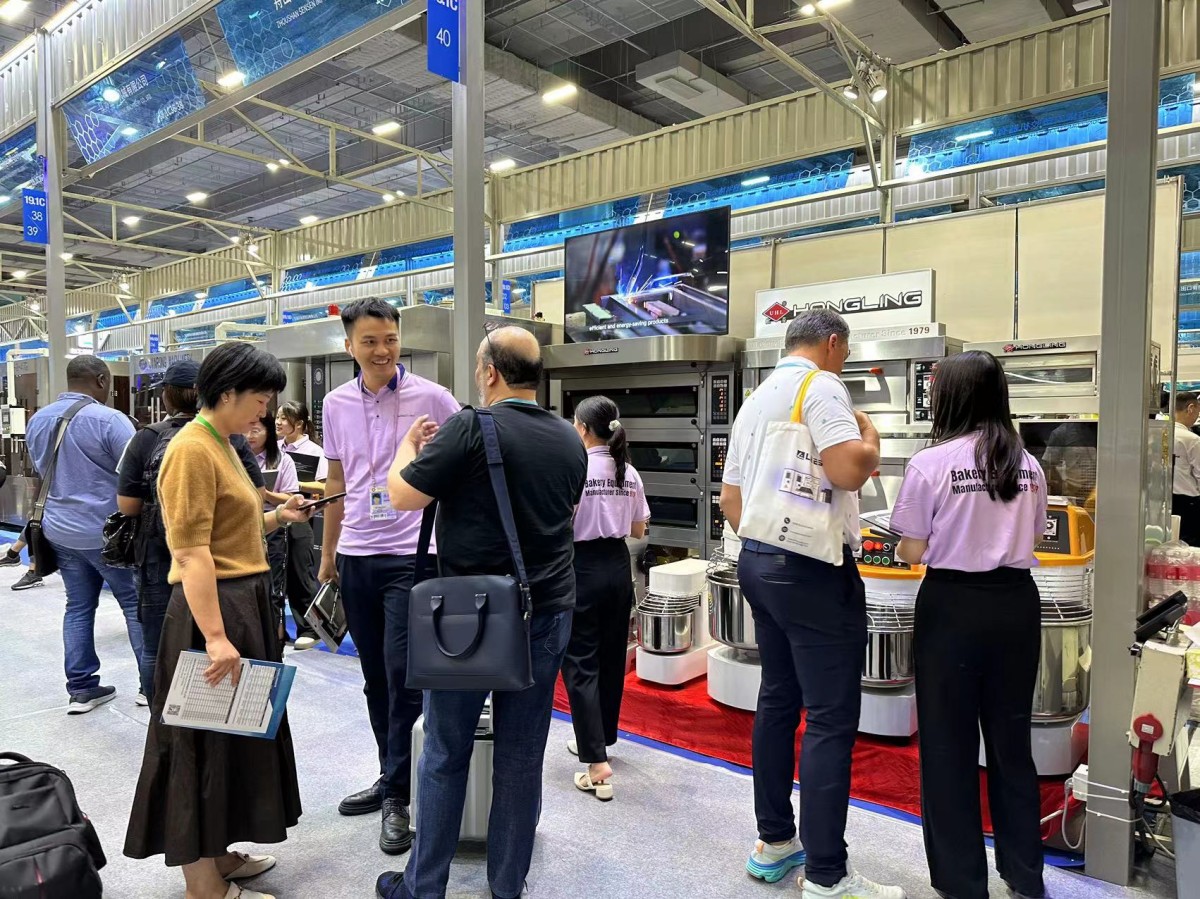

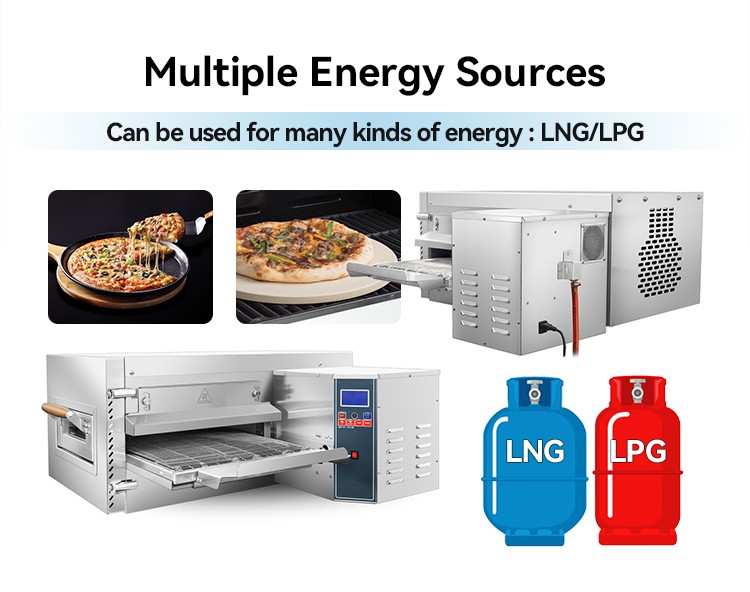

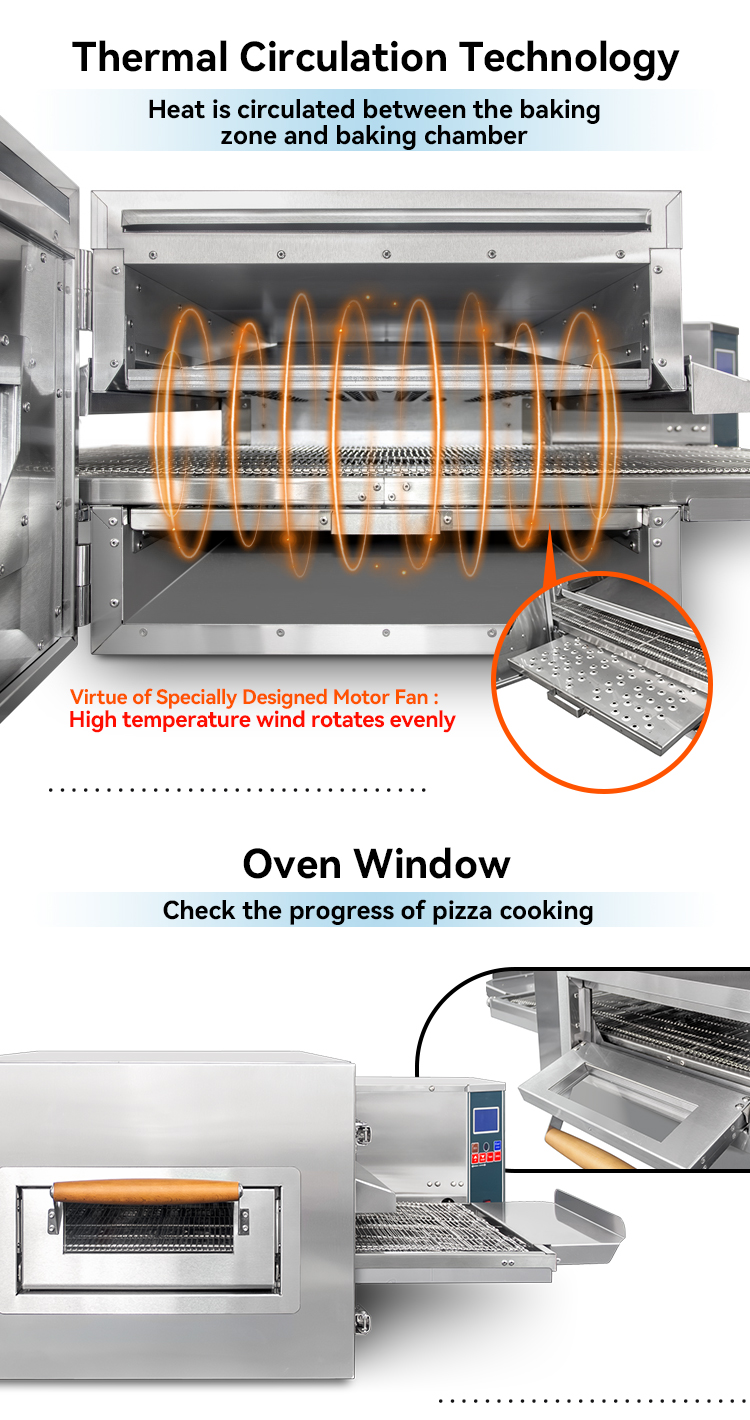

Hongling rotary oven has three heating sources:gas,diesel and electric.This machine could be used for baking many kinds of products,such as cake,bread,cookie,moon cake,pastry,and so on.The internal and external are full stainless steel 201. It combines hot air convection,heating air circulation,and trolley slow rotation to ensure the products inside are heated evently. It has a spray and humidification device to guarantee the food to meet the humidity requirement. It also has lighting system inside,customer can observe the whole baking process through glass of door. After baking,the products are uniformly ripening.

Features of a Rotary Rack Oven

1.Rotating Rack System: The key feature of a rotary rack oven is its rotating rack, which helps in achieving uniform baking. The rotation ensures that all the products receive the same amount of heat.

2.Consistent Temperature: These ovens are equipped with advanced temperature control systems to maintain consistent heat, which is crucial for producing high-quality baked goods.

3.High Capacity: Rotary rack ovens can hold multiple racks of baking trays, making them ideal for large-scale baking operations.

4.Efficient Heat Distribution: The design of these ovens ensures efficient heat distribution, reducing baking times and improving energy efficiency.

5.Versatility: Rotary rack ovens can be used to bake a wide variety of products, including bread, pastries, cakes, cookies, and more.

6.Steam Injection: Many rotary rack ovens have steam injection capabilities, which are essential for certain types of bread and pastries that require a crispy crust.

7.Programmable Controls: Modern rotary rack ovens often come with programmable controls, allowing bakers to set specific baking times, temperatures, and steam cycles for different products.

Benefits of Using a Rotary Rack Oven

1.Uniform Baking: The rotating rack ensures that all products are baked evenly, reducing the chances of hot spots or unevenly baked goods.

2.Increased Production: With the ability to bake large quantities at once, rotary rack ovens increase production efficiency and output.

3.Labor Efficiency: These ovens reduce the need for manual intervention, allowing bakers to focus on other tasks.

4.Energy Efficiency: The efficient heat distribution and insulation of rotary rack ovens contribute to lower energy consumption.

5.Improved Product Quality: Consistent and precise baking conditions result in higher quality baked goods with better texture and flavor.

Considerations When Choosing a Rotary Rack Oven

1.Capacity: Consider the volume of products you need to bake and choose an oven with the appropriate capacity.

2.Size: Ensure the oven fits within your bakery's space and can accommodate your baking trays and racks.

3.Energy Source: Rotary rack ovens can be powered by gas or electricity. Choose the one that best suits your bakery's setup and energy availability.

4.Features: Look for features such as steam injection, programmable controls, and self-cleaning options that can enhance your baking process.

5.Brand and Warranty: Choose a reputable brand that offers good customer support and a reliable warranty.

Maintenance Tips

1.Regular Cleaning: Clean the oven regularly to prevent buildup of food particles and grease, which can affect baking quality and oven performance.

2.Inspect Components: Regularly inspect the rotating mechanism, heating elements, and control systems to ensure they are functioning properly.

3.Professional Servicing: Schedule professional maintenance checks to keep the oven in optimal condition and extend its lifespan.

A rotary rack oven is a valuable investment for any commercial bakery, offering efficiency, consistency, and versatility in baking operations.