Laundry pods counting packaging solution

With the rapid development of household cleaning products market, laundry pods as a new type of washing products are widely welcomed because of their convenient use, accurate dosage and environmental protection characteristics. However, in the high-speed production line, the packaging counting of laundry pods faces many challenges.

The VX series vision counting machine plays an important role in the laundry pods counting and packaging production line. The following is a case of a well-known daily chemical enterprise customer. As shown in the following video, VX8-3 vision counting machine is demonstrated.

Solution

The elevator is equipped with an 8-channel design to meet customer production requirements, such as 15 per pack/box, the speed can reach 40-50 per pack/box per minute,

At the same time, the channel combination counting can be used to achieve more quantity counting packaging, such as 40 per pack/box, and the speed can reach 15-25 per pack/box per minute.

Advantage for VX8-3 counting machine

1.Can count quickly and accurately.

2.Strong compatibility, whether single chamber, multi-chamber, can achieve counting.

3.The product information can be traced, and the whole set of equipment can be linked with the enterprise management system

4.Intelligent learning function to reduce parameter debugging time

5.Through the learning mode, the data of various falling postures of materials can be automatically obtained, and the accuracy of parameters can be checked through the verification mode. If there is an error, the parameters can be manually fine-tuned. A material only needs to be learned and verified once, and the next time it is used, it can be directly retrieved.

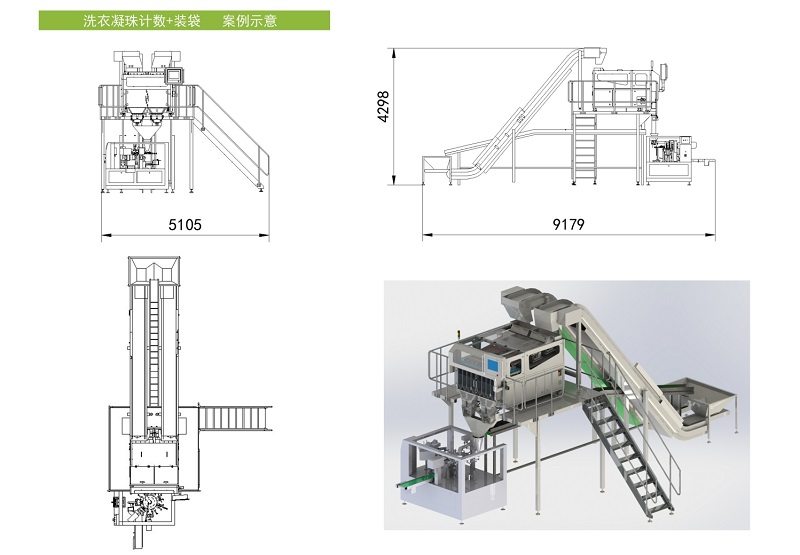

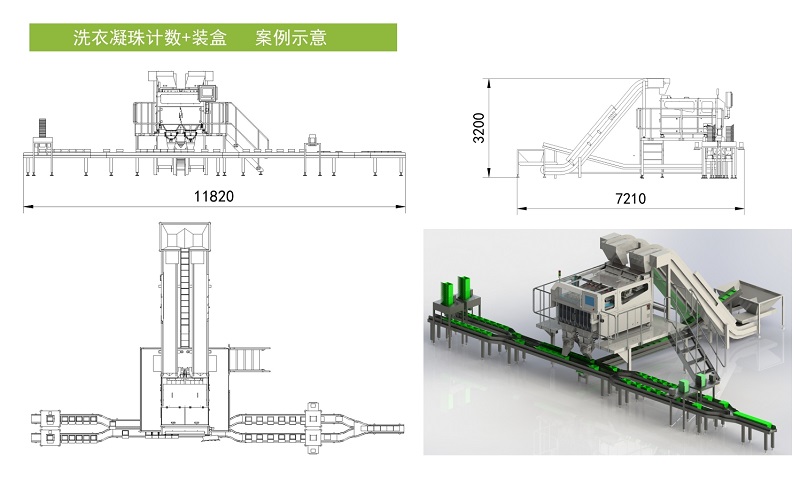

The counting machine can be paired with bag or box production line according to customer’s requirements.The following is a schematic diagram of the bagging and box production line.

The successful application of the VX8-3 vision counter in the laundry detergent industry not only addresses the of traditional counting methods but also provides a reliable solution for the intelligent upgrade of the daily chemical industry. As algorithms continue to optimize and hardware performance improves, vision counting technology will play a crucial role in more niche areas, driving the packaging industry towards greater efficiency and precision.