In the "last mile" of cement production—the loading of bagged cement—we seem to be trapped in a persistent predicament.

Walk into any traditional cement plant's loading site, and you'll likely see this scene: billowing dust blurs visibility, workers wrapped in heavy protective suits and masks struggle to navigate between trucks and conveyor belts. This isn't just a matter of efficiency; it's a severe test of occupational health, environmental protection, and corporate costs.

The continuous rise in labor costs, increasingly stringent environmental regulations, and the relentless pursuit of operational efficiency have collectively propelled "fully automated loading" to the forefront of industry transformation. However, as we embrace automation with high hopes, we find that existing solutions on the market always fall short.

Today, we'll delve into why traditional automated loading solutions have consistently failed to truly "end" this industry ailment.

A Visual Comparison of Three Mainstream Solutions: The Ideal is Beautiful, the Reality is Harsh

The market has not been without attempts. Currently, mainstream automated cement loading solutions fall into three main categories, but each has its own significant technological hurdles. We have created the following diagram to clearly illustrate their core challenges:

| Scheme type | Core Principles | Advantages | Fatal Flaw |

| Robotic loading arm | To mimic human operation, large industrial robots are used to grab and stack material bags. | It is highly flexible and can theoretically be adapted to various vehicle models. | The dust pollution is enormous: the grabbing and throwing actions can easily break the bags, causing explosive dust leaks. |

| Package loading head | Materials are sequentially dropped and stacked through multiple discharge ports and sliding trolleys. | The structure is relatively simple and the control logic is straightforward. | Maintenance nightmare: The equipment has a compact structure, extremely narrow maintenance space, and long downtime due to malfunctions. |

| High-sideboard solution | A top-loading system designed for standard vans. | Loading speed is fast, and dust control is acceptable. | Extremely poor adaptability: It cannot handle high-sided, flatbed, or modified vehicles, greatly reducing its practicality. |

The pain points are immediately apparent.

Figure 1: Robotic arm loading truck – “Dust generator”

(When traditional robotic arms grab and throw cement bags, the resulting dust clouds engulf the entire work area, severely reducing visibility. This is not only pollution, but also a huge safety hazard and a significant waste of materials.)

Figure 2: High-sided trucks – “An insurmountable gap”

(A high-sided truck is parked under traditional loading equipment; the Jeenar loading equipment lowers the load far below the sideboards, only 60cm from the bottom of the truck bed.)

The root cause of the predicament: What do we really need?

Looking at the above solutions, we find a common thread: they are all “patches and repairs” on the existing technological framework, failing to fundamentally understand and solve the core needs of the loading process. A truly qualified automated loading solution must simultaneously meet the following four points:

Environmentally friendly and dust-free: Suppressing dust at the source, protecting worker health, and meeting the environmental protection requirements of “green mountains and clear waters.”

Stable and efficient: High equipment reliability, convenient maintenance, and the ability to achieve continuous and stable operation 24/7, significantly improving delivery efficiency.

Widely adaptable: It must be able to easily handle the large number of non-standard vehicles present in the Chinese market, such as high-sided trucks, flatbed trucks, and agricultural vehicles.

High return on investment: Not only must it be affordable to buy, but also affordable to use and repair, with overall costs superior to manual labor teams.

Unfortunately, traditional robotic arms, stacking heads, and high-sided pallet solutions all have significant shortcomings on different sides of this "perfect quadrilateral."

The Solution: A Leap in Thinking from "External Stacking" to "Internal Operation"

So, where does the solution lie?

If existing solutions merely involve "airdropping" from outside the wagon, then no matter how sophisticated the movements, dust, bag breakage, and adaptability issues are unavoidable.

Gachn's answer is based on this fundamental leap in thinking: Why not operate inside the wagon?

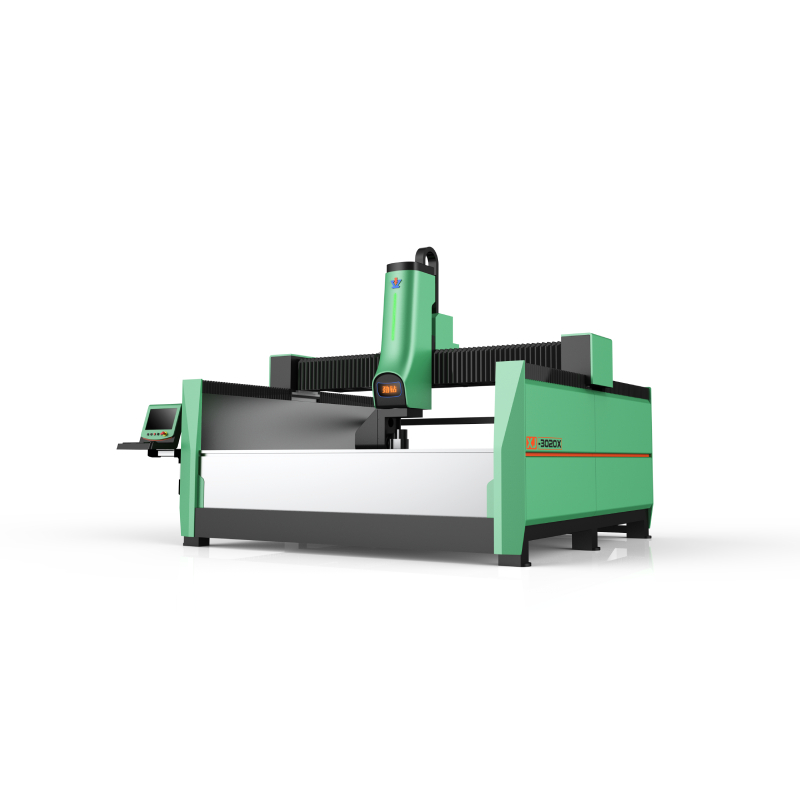

This is precisely the design philosophy behind our innovative "in-carriage" automated loading system. It is no longer a simple "loading machine," but an intelligent, precise, and dust-free "in-carriage robot."

Direct Dust Control: Through a unique dust suppression design and gentle, precise stacking inside the wagon, dust from high-altitude drops and throwing is physically eliminated.

Direct Maintenance: A modular design makes maintenance of key components readily accessible, minimizing the Mean Time To Repair (MTTR).

Directly facing vehicle types: The innovative telescopic and rotating mechanism allows it to "penetrate" deep into the interiors of various high-sided and irregularly shaped truck bodies, achieving full coverage operation.

Conclusion: The industry's pain points are the starting point for our innovation. We deeply understand that on the journey of automated cement loading, there is no shortage of solutions, but a lack of solutions that truly "solve the problem."