With advancements in technology, the demand for electric motors operating in extreme environments has grown significantly. Among these, vacuum environments pose unique challenges for electric motors. This article explores how motors can function properly in a vacuum and introduces some typical application cases.

I. Special Requirements for Motors in a Vacuum Environment

A vacuum environment (typically defined as pressure below 1×10⁻⁵ Pa) affects motor operation in several ways:

Heat Dissipation Issues: The absence of air convection in a vacuum renders traditional cooling methods ineffective.

Material Outgassing: Certain materials release gases in a vacuum, contaminating the environment.

Lubrication Challenges: Conventional lubricants tend to evaporate or decompose in a vacuum.

Electrical Insulation Problems: The performance of insulating materials may change under vacuum conditions.

Thermal Expansion Differences: Variations in thermal expansion coefficients between materials become more pronounced with temperature changes.

II. Key Technologies for vacuum compatible motors

1. Special Heat Dissipation Designs

Use of high thermal conductivity materials (e.g., copper, aluminum) for housing

Design of heat-radiating fins to increase surface area for radiative cooling

Integration of heat pipes or liquid cooling systems (for high-power motors)

2. Selection of Vacuum-Compatible Materials

Use of low-outgassing materials (e.g., stainless steel, ceramics, specialty plastics)

Avoidance of high-outgassing materials like rubber and standard plastics

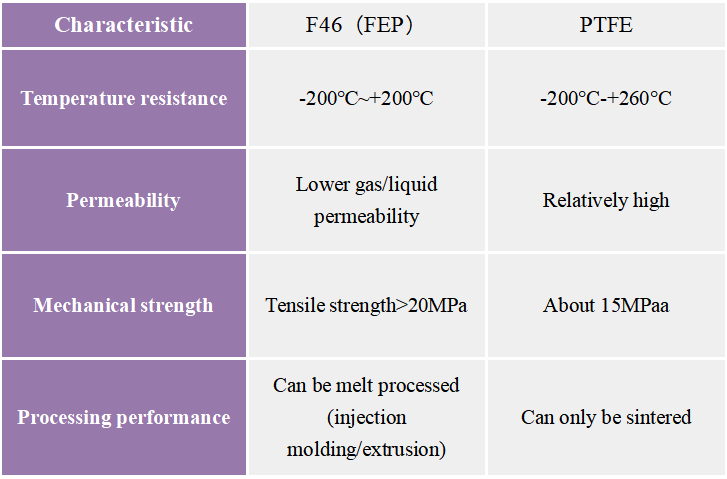

Selection of vacuum-compatible insulating materials (e.g., polyimide, PTFE)

3. Special Lubrication Systems

Use of solid lubricants (e.g., molybdenum disulfide, graphite)

Application of specialized vacuum-compatible greases

Design of self-lubricating bearing systems

4. Sealing Technologies

Use of metal seals or specialized elastomer seals

Design of multi-stage sealing systems

Consideration of thermal stress effects on seals

5. Special Electromagnetic Design

Optimized winding design to minimize heat generation

Consideration of corona discharge in a vacuum

Use of high-temperature-resistant electromagnetic materials

III. Typical Application Cases of Vacuum Motors

1. Aerospace Applications

Satellite Attitude Control Motors: Used for adjusting solar panels and Earth orientation.

Space Robotic Arm Drive Motors: Employed in the International Space Station and satellite servicing missions.

Rocket Propulsion System Valve Control Motors: Regulate fuel and oxidizer flow.

2. Semiconductor Manufacturing

Wafer Handling Robot Motors: Transport silicon wafers inside vacuum chambers.

Lithography Machine Precision Positioning Motors: Enable nanometer-level positioning accuracy.

Vacuum Deposition Equipment Rotary Motors: Ensure uniform coating deposition.

3. Scientific Research Equipment

Particle Accelerator Vacuum Pump Motors: Maintain ultra-high vacuum conditions.

Fusion Reactor Internal Drive Motors: Used in tokamak devices for various actuators.

Space Simulation Chamber Equipment Motors: Simulate space environments for testing on Earth.

4. Medical Devices

Proton Therapy System Gantry Motors: Precisely position patients in a vacuum environment.

Electron Microscope Stage Drive Motors: Enable nanometer-level sample movement.

5. Industrial Equipment

Vacuum Metallurgical Furnace Drive Motors: Handle materials in high-temperature vacuum conditions.

Vacuum Coating Production Line Conveyor Motors: Transport substrates in continuous production processes.

IV. Development Trends in Vacuum Motors

Higher Power Density: Deliver greater torque in limited spaces.

Longer Lifespan: Reduce maintenance needs, especially for space applications where repairs are difficult.

Smarter Control: Integrate sensors for condition monitoring and adaptive control.

New Material Applications: Use of advanced materials like carbon nanotubes and graphene.

Modular Design: Facilitate quick adaptation for different vacuum applications.

Conclusion

Motor technology for vacuum environments is a critical enabler for multiple high-tech industries. With advancements in materials science, thermal management, and precision manufacturing, the performance of vacuum motors will continue to improve, expanding their range of applications. In the future, vacuum motors will play an even more significant role in cutting-edge fields such as deep-space exploration, quantum technology, and next-generation semiconductor manufacturing.