Banana farming is a significant part of the agricultural sector, especially in tropical and subtropical regions. However, growing bananas is no easy task. From managing large plantations to ensuring high-quality yields, farmers face various challenges. But now, technological advancements like agricultural drones are revolutionizing banana farming, offering solutions to old problems and improving productivity.

Agricultural drones, particularly high-tech models like the FP700, are increasingly being used in banana farming for a variety of essential tasks. These drones help farmers manage their plantations more effectively and efficiently, ensuring healthier crops and higher yields.

One of the main challenges in banana farming is pest and disease management. Bananas are highly susceptible to fungal infections, pests like the banana weevil, and diseases. Traditionally, spraying pesticides and fungicides was a labor-intensive task, but agricultural drones are transforming the mode.

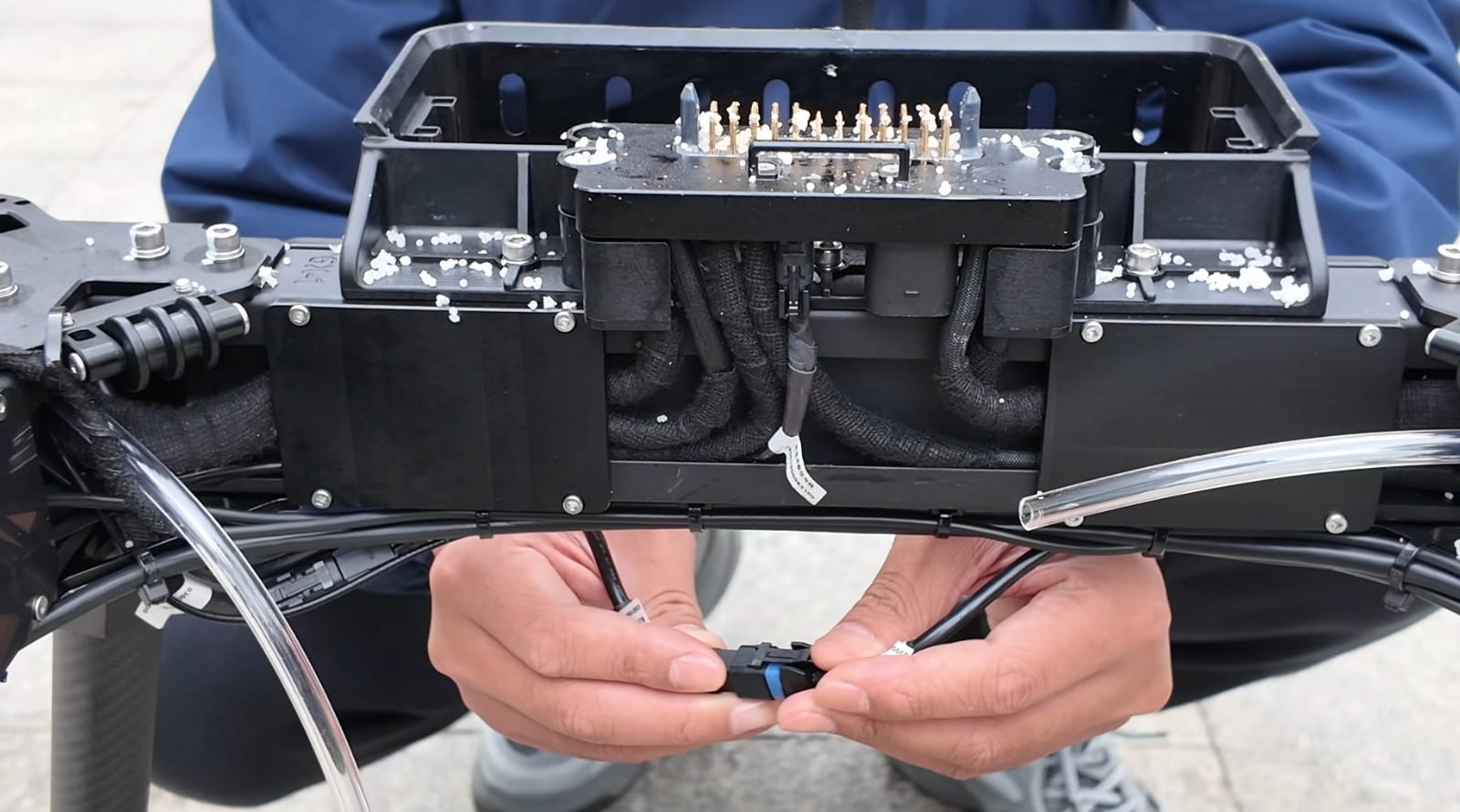

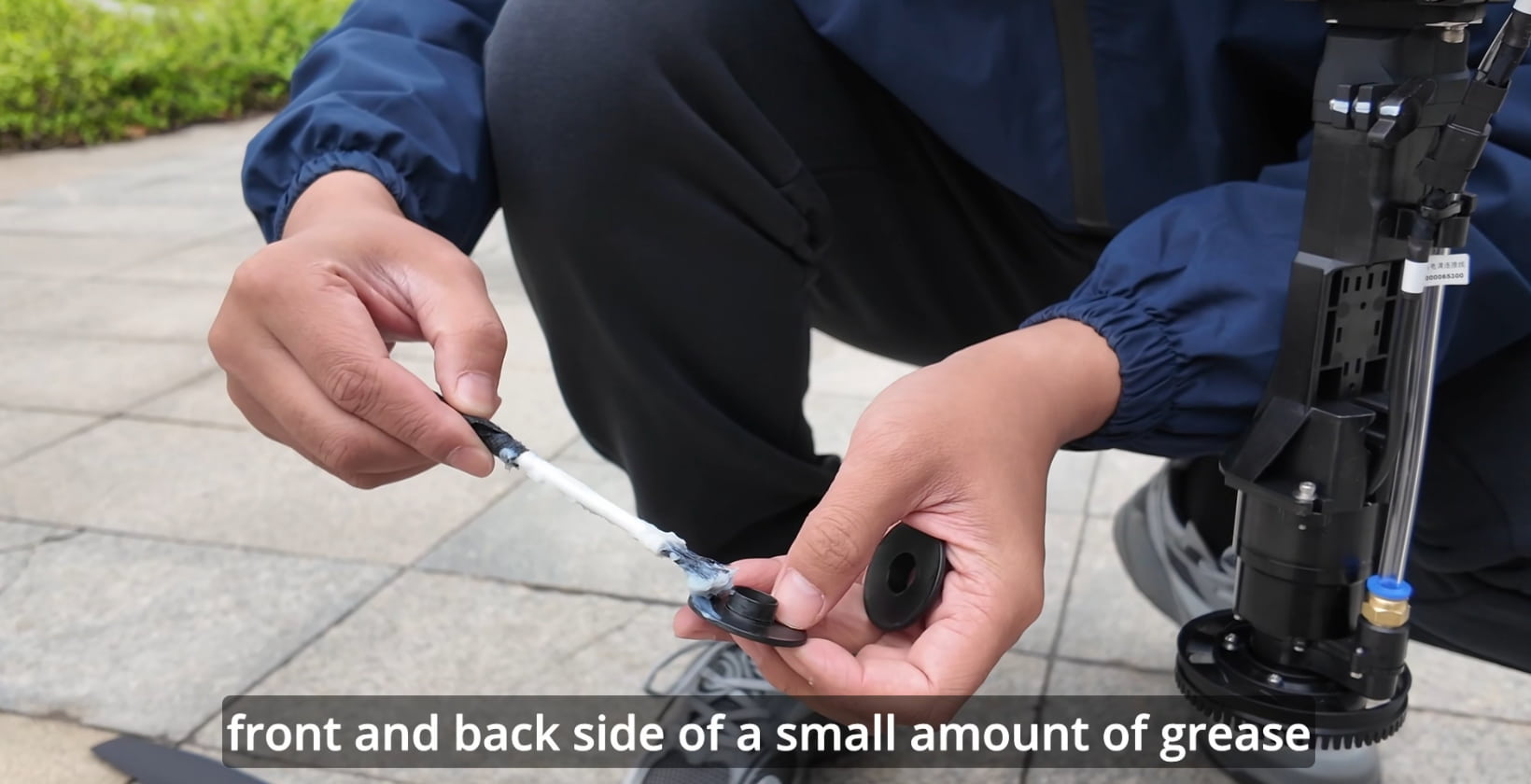

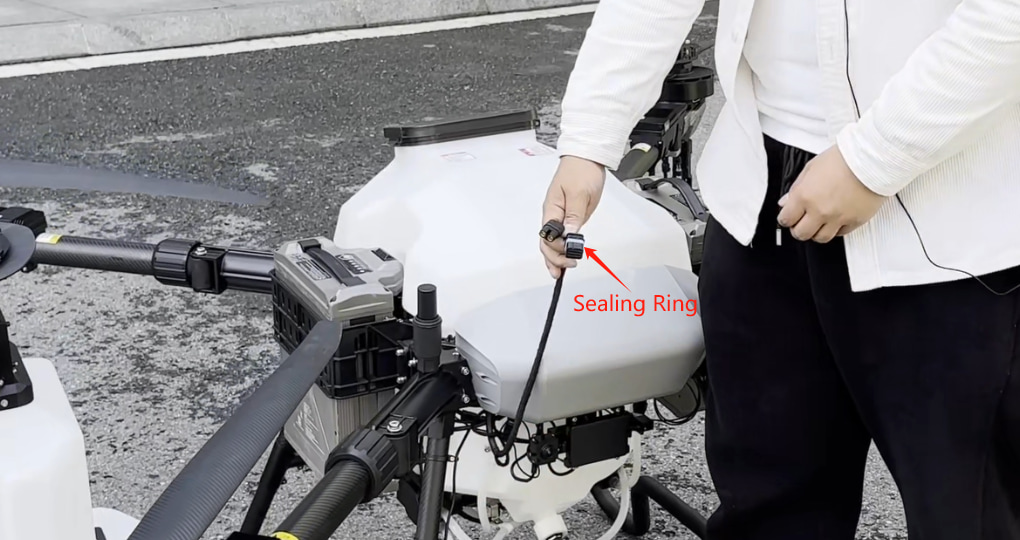

Equipped with advanced spraying systems, drones can apply fertilizers, pesticides, and fungicides with precision. The FP700 agri drone, for example, uses a rear-mounted centrifugal nozzle system that delivers high-flow sprays at a consistent rate, ensuring even coverage across the plantation. This precision reduces the risk of over-application, saves on chemicals, and protects the environment, all while ensuring the health of the banana plants.

Banana plants require a steady supply of nutrients to grow strong and healthy. However, manually distributing fertilizers across large banana plantations can be challenging and time-consuming. With agri drones’ spreader system, it offers a more efficient solution. They can precisely distribute fertilizers, compost, or other soil amendments at the right amount and in the right places, ensuring that the banana plants get the nutrients they need for optimal growth.

In large banana plantations, it can be difficult to track plant health and spot potential issues early. Traditional methods, like manual inspection, can be time-consuming and may miss crucial problems. However, drones equipped with mapping cameras are transforming this process.

Agricultural drones significantly reduce the need for manual labor by automating tasks such as spraying, spreading, and monitoring. With agricultural drones’ autonomous flight capabilities, allows farmers to focus on other aspects of farm management while the drone handles key tasks. With a payload capacity of up to 70kg, FP700 can carry large amounts of spray or fertilizer, improving operational efficiency and reducing the time it takes to cover large fields.

Agriculture has a significant environmental impact, and banana farming is no exception. However, drones are helping farmers make their practices more sustainable. By applying precise amounts of pesticides, fertilizers, and water, drones reduce waste, which lowers the environmental footprint of banana farming. Additionally, drones are much more efficient in terms of time and labor, reducing the need for machinery that contributes to carbon emissions.